CNC Contour Cutting

CNC Contour Cutting

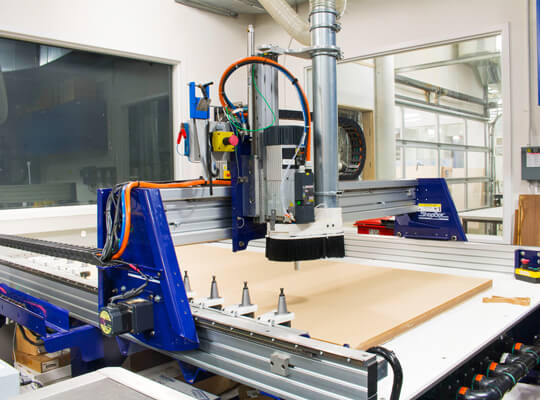

CNC contouring cutting, also called CNC contour milling, is the most typical fabrication technique to produce 3D foam shape products. The contour cutter uses a high-speed grinding blades or wire to cut the foam into various shapes, curves and diameters. Compared with foam die cutting, CNC contouring cutting functions without tooling cost. As both horizontal and vertical contour cutting are controlled by computer program, they can precisely cut foam into required profile nicely.

Broadly speaking, CNC contouring cutting includes CNC horizontal cutting, vertical linear cutting and hot wire cutting and so on. With CNC cutting machines, complicated foam profile shapes can be easily achieved with high precision. CNC contouring cutter is ideally used for making foam packaging or other thick foam components.

CNC contouring cutting works well with EVA foam, Polyethylene foam and Polyurethane foam for making all types of foam insert packaging, industrial foam parts and protective foam parts. Another benefit is that this foam fabrication technique can make less foam material waste during production.

Main Advantages:

- High efficient machinery to custom cut complicated foam profile and shape

- Capable of horizontally and vertically cut foam

- Without tooling cost and with tight tolerance

Related Foam Material:

- EVA Foam

- Polyethylene Foam

- Polyurethane Foam

Applications:

- Foam Composites

- Foam Packaging

- Protective Foam Inserts

- Complicated Foam Components