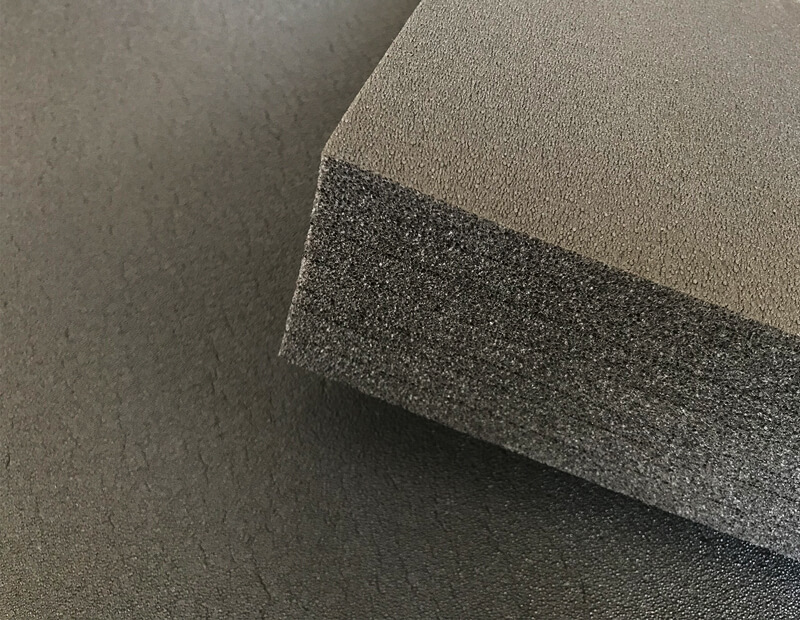

Polyethylene Foam

Different from open cell Polyurethane foam, Polyethylene foam is one kind of closed cell foam materials. Polyethylene foam is also one typical extruded foam, not like EVA foam which is produced in foam buns by molding methods. But PE foam material comes in large and long roll due to its foaming method. PE foam sheets can also reach to large thickness by using laminating several thin sheets together. They come out with various densities and colors upon custom requirements. But white, black and gray are basic color for PE foam sheets. Its density varies from 28kg/m3 up to 200kg/m3.

All types polyethylene foam are with cross linked foam structure, but they are categorized in two main types, chemically crosslinked Polyethylene foam (XPE or XLPE Foam) and Irradiated crosslinked Polyethylene foam (IXPE Foam). The first one is cost effective type of PE foam, and the last one is a high level version of Polyethylene foam with better properties. Polyethylene foam are widely used on various industries such as packaging, construction and marine due to its excellent performance on cushioning, insulation, buoyancy and durability.

Physical Properties:

- Extruded foam materials in rolls

- Closed cell foam structure

- Moisture and heat insulation

- Long term durability and tear resistance

- Available in various custom densities and colors

- Odorless and weather resistance

Features & Benefits:

- Offered in foam roll and can be laminated to make thick foam sheets

- Easy to be fabricated into various foam products

- Excellent at impact impact absorption, waterproofing and acoustic insulation

- Availability of flame retardant property

Applications & Industries:

- Construction and Building

- Foam Packaging Applications

- Cushioning Foam Products

- Flooring Underlay

- Industrial Foam Components

- Marine Products

- Heat and Moisture Insulation Solution

- Other Foam Fabrication Products