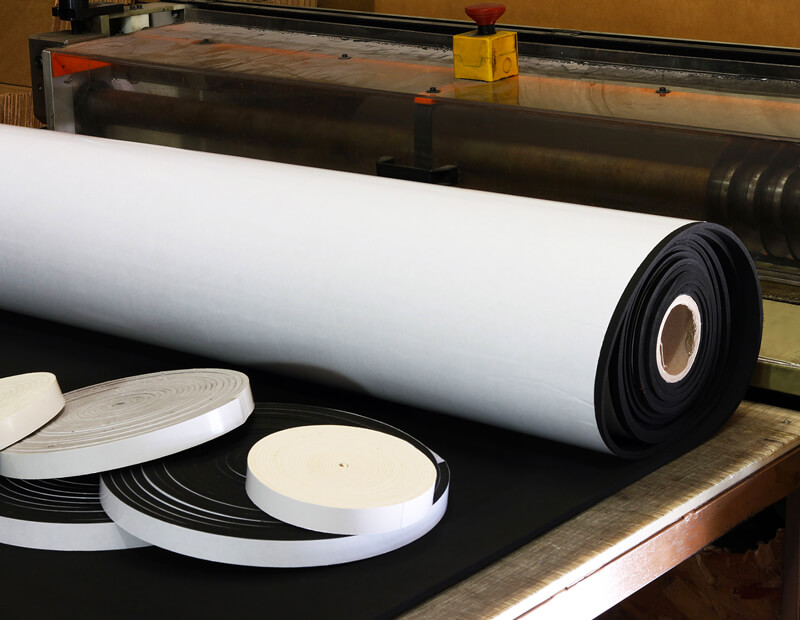

Foam Rubbers

Foam rubbers are a large family inside foam materials includes EPDM foam, neoprene foam (CR foam), SBR foam. EPDM foam can be specially made in open cell structure, and the rest two kinds of foam rubbers are only available in closed cell foam structure. All foam rubbers result in high elasticity, flexibility and resilience. They are naturally good at impact absorption, weather resistance, UV resistance and tear resistance. Among them, EPDM foam has great performance on abrasion and skid-resistance. Neoprene foam rubber is more durable with good tear strength property. SBR sponge rubber is the most cost-effective one compared with EPDM foam rubber and Neoprene foam rubber, and it is usually laminated with fabric for making waterproofing textile for watersports. All of the three foam rubbers are quite suitable for fabricating foam sealing gaskets and foam rubber tapes in various custom shapes and sizes.

Physical Properties:

- Closed cell foam rubber materials

- Good tear strength for long term durability

- Flexible, cushioning and resilient foam

- Working under a wide range of temperature

- Superior low compression set

Features & Benefits:

- Providing excellent performance at sealing, cushioning and insulation

- Easily fabricated into custom size foam pad, sheets, tapes and gaskets

- Resistance to oil, chemical, moisture, UV and weather

- Flexible and durable for long term usage at various applications

Applications & Industries:

- Cushion Foam Parts

- Industrial Sealing and Insulation

- Impact Dampening Parts

- Automotive

- Transportation

- Construction

- Electronics

- Other Foam Fabrication Products