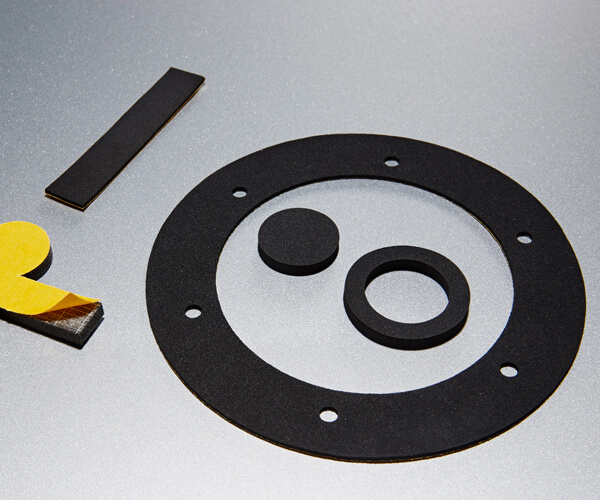

Foam Gaskets

Foam gaskets, also known as foam washer or sponge gaskets, are widely used for a broad range of applications and industries. Usually fabricated by steel die-cutting technique and flatbed compression cutting, foam gaskets can be made into any custom shapes and sizes. The finished foam rubber gaskets can also be laminated with PSA adhesive backing that helps gasket stick to applied items. You can see foam sealing gaskets frequently used for insulation, cushion, waterproof, vibration and sound reduction applications. Both open cell foam and closed cell foam can be easily made as foam gaskets.

Foam Materials:

- EVA Foam

- Polyethylene Foam

- Polyurethane Foam

- Polypropylene Foam

- Vinyl Nitrile Foam

- Silicone Foam

- PVC Foam

- Foam Rubbers – Neoprene foam, EPDM foam and SBR foam

Fabrication Capability:

- Skiving Cutting

- Bandsaw Cutting

- Die Cutting

- Compression Cutting

- Foam Lamination

- CNC Contour Cutting

Features & Benefits:

- Custom cut into various shapes and sizes

- Available with PSA adhesive backing for easy usage

- Made with a wide range of both open cell and closed cell foam material

Applications & Industries:

- Automotive and Transportation

- Protective Liner

- Industrial Foam Parts

- Medical Foam Parts

- Sealing and Insulation Application

- Soundproof and Cushion Application

![Foam Gasket with Adhesive Backed]](https://www.foaminsider.com/wp-content/uploads/2019/05/Foam-Gasket-with-Adhesive-Backed.jpg)